-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

Método de tratamiento térmico

• Generalmente, carburo cementado se coloca en un horno de atmósfera protectora tal como un horno de vacío o un horno de hidrógeno. Mediante el tratamiento de templado a baja temperatura, la temperatura suele rondar los 200-300 grados Celsius, lo que puede reducir eficazmente la tensión residual dentro de la aleación causada por el procesamiento, etc., y no afectará las propiedades principales del carburo cementado, como la dureza.

envejecimiento natural

• Es colocar la pieza de trabajo de carburo cementado en un ambiente interior durante un período prolongado, generalmente varios meses, para permitir que la tensión dentro de la aleación se libere naturalmente. Sin embargo, este método requiere mucho tiempo y es relativamente ineficiente.

Además del revenido a baja temperatura, también se pueden utilizar los siguientes métodos para eliminar la tensión interna en el carburo cementado:

Envejecimiento por vibración

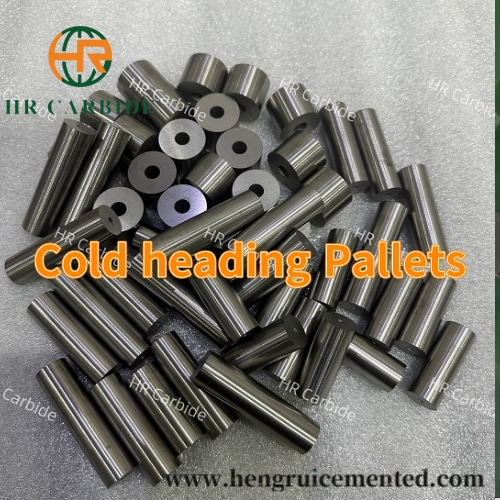

• Sostenga la pieza de trabajo de carburo cementado con un dispositivo elástico y troquel de cabeza fría de carburo de tungsteno hacer vibrar la pieza de trabajo a través de un dispositivo de vibración. Durante el proceso de vibración, la estructura cristalina dentro de la pieza de trabajo sufrirá cambios microscópicos y la tensión se redistribuirá y liberará. Generalmente, la vibración durante unas horas puede tener cierto efecto de alivio del estrés. Este método requiere poco tiempo, es muy eficaz y relativamente sencillo de utilizar.

Tratamiento criogénico

• Coloque el carburo cementado en un ambiente de baja temperatura (como nitrógeno líquido, la temperatura puede ser tan baja como -196 ℃), manténgalo por un período de tiempo y luego sáquelo. Durante el rápido cambio de temperatura, la estructura interna de la aleación cambia, de modo que se libera la tensión residual. El tiempo de tratamiento puede variar desde varias horas hasta decenas de horas, según el tamaño de la pieza de trabajo y otras condiciones.

ETIQUETAS :