-

Make a Call : +8618034073113

-

Get A Estimate : hengrui@hrcarbide.cn

Make a Call : +8618034073113

Get A Estimate : hengrui@hrcarbide.cn

Complejidad de los rollos de TC en la fabricación de laminación en frío y en caliente

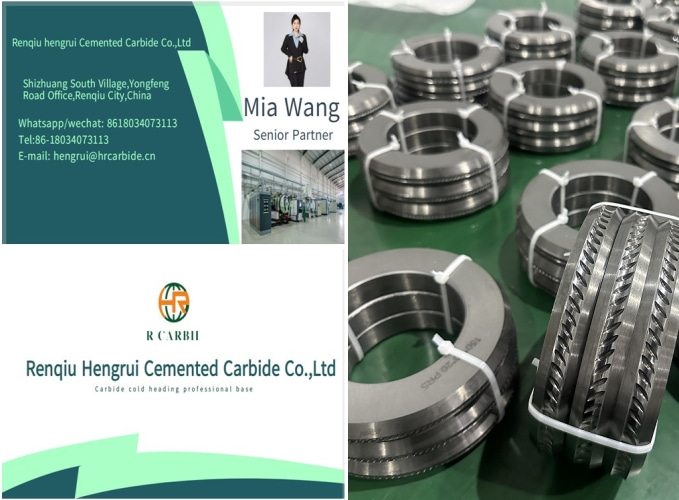

La fabricación ha dependido durante mucho tiempo de diversos procesos de laminación para dar forma a los metales según las especificaciones deseadas. Entre estos procesos, el laminado en frío y el laminado en caliente son los dos métodos más populares. Central para estos procesos es el uso de Rollos de CT o rodillos de carburo de tungsteno, que desempeñan un papel vital para garantizar la calidad y eficiencia de las operaciones de laminación. Este artículo analiza en profundidad la importancia de los rollos de TC en la fabricación de laminados en frío y en caliente, explorando sus ventajas, aplicaciones y avances tecnológicos para mejorar su rendimiento.

Comprender el volumen de TC

Los rodillos de carburo de tungsteno (TC) son conocidos por su excepcional dureza y resistencia al desgaste, lo que los hace ideales para aplicaciones de laminación exigentes. Compuestos por partículas de carburo de tungsteno unidas por un aglutinante metálico, generalmente cobalto, los rodillos TC ofrecen una durabilidad superior en comparación con los rodillos de acero tradicionales. Esta composición única permite que los rodillos TC resistan las altas presiones y temperaturas encontradas durante el proceso de laminación, lo que garantiza un rendimiento constante y una vida útil prolongada.

Laminación en frío del rollo TC

La laminación en frío es un proceso de trabajo del metal que implica pasar el metal a través de un par de rodillos a temperatura ambiente para reducir su espesor y mejorar su acabado superficial. Los rodillos TC son particularmente ventajosos en el laminado en frío debido a su capacidad para mantener la precisión dimensional y la calidad de la superficie a largo plazo. La rigidez del rodillo TC Minimiza el desgaste y la deformación, lo que resulta en una reducción precisa y uniforme del espesor. Además, la superficie lisa del rollo TC ayuda a producir productos terminados de alta calidad con defectos superficiales mínimos.

En el proceso de laminación en frío, los rodillos TC se utilizan a menudo junto con otros tipos de rodillos, como rodillos de trabajo y rodillos de respaldo, para lograr la reducción de espesor requerida. La combinación de rodillos TC con estos rodillos auxiliares aumenta la eficiencia general del proceso, aumentando así la productividad y reduciendo el tiempo de inactividad. Además, utilizando Rollos de CT El laminado en frío puede generar importantes ahorros de costos al reducir la frecuencia de reemplazo y mantenimiento de los rodillos.

Rodillo TC laminado en caliente

La laminación en caliente, por otro lado, implica laminar metal a altas temperaturas, generalmente por encima de la temperatura de recristalización del material. El proceso se utiliza para producir una variedad de productos que incluyen láminas, paneles y componentes estructurales. Las tiradas de TC también son valiosas en rollos de laminación en caliente aplicaciones debido a su capacidad para soportar temperaturas extremas y estrés mecánico.

Una de las principales ventajas de utilizar Rollos TC en laminación en caliente es su resistencia a la fatiga térmica y a la oxidación. Las altas temperaturas que se encuentran durante el laminado en caliente pueden hacer que los rollos de acero tradicionales se degraden rápidamente, provocando defectos en la superficie y reduciendo la calidad del producto. Sin embargo, incluso en estas duras condiciones, los rollos TC mantienen su integridad y rendimiento, lo que garantiza una calidad constante del producto y reduce la necesidad de reemplazos frecuentes de los rollos.

Rodillo TC Avances en la tecnología de fabricación

En los últimos años, se han logrado avances significativos en la fabricación de rollos de TC debido a la necesidad de mejorar el rendimiento y la rentabilidad. Un avance notable es el uso de tecnología avanzada de pulvimetalurgia para producir rodillos de TC con propiedades mejoradas. Estas tecnologías implican un control preciso del tamaño de las partículas, la distribución y el contenido de aglutinante, lo que da como resultado rodillos TC con dureza, tenacidad y resistencia al desgaste optimizadas.

Otro avance importante es la aplicación de recubrimientos y tratamientos superficiales para mejorar aún más el rendimiento de los rodillos TC. Por ejemplo, el uso de recubrimientos de carbono tipo diamante (DLC) puede reducir significativamente la fricción y el desgaste, extender la vida útil de los rodillos TC y mejorar la calidad de los productos laminados. Además, se pueden utilizar procesos avanzados de tratamiento térmico para ajustar la microestructura del rodillo TC y mejorar su capacidad para resistir la fatiga térmica y el estrés mecánico.

Aplicación y perspectivas de futuro

La versatilidad y durabilidad de los rollos TC rollos de carburo de tungsteno los hacen indispensables en una variedad de aplicaciones rodantes. Además del laminado en frío y el laminado en caliente, los rodillos TC también se utilizan en otros procesos como el trefilado, el laminado de tubos y el laminado de perfiles. Su capacidad para mantener la precisión dimensional y la calidad de la superficie en condiciones exigentes los convierte en la primera opción en industrias como la automovilística, la aeroespacial y la construcción.

De cara al futuro, los rodillos TC tienen amplias perspectivas en el campo de la fabricación de laminados. Los esfuerzos continuos de investigación y desarrollo se centran en mejorar aún más el rendimiento y la rentabilidad de los rollos de TC. Las innovaciones en la ciencia de los materiales, como el desarrollo de nuevas composiciones de carburo y sistemas adhesivos, tienen el potencial de mejorar aún más el rendimiento de los rodillos TC. Además, los avances en las tecnologías de fabricación, como la fabricación aditiva y la nanotecnología, pueden allanar el camino para producir rodillos TC con niveles de precisión y rendimiento sin precedentes.

en conclusión

En resumen, los rodillos TC desempeñan un papel clave en la fabricación de laminación en frío y en caliente, ofreciendo dureza, resistencia al desgaste y durabilidad incomparables. Son capaces de soportar las duras condiciones del proceso de laminación, lo que garantiza una calidad constante del producto y una vida útil prolongada. Los avances en la tecnología de fabricación de rollos de TC han mejorado aún más su rendimiento, haciéndolo indispensable en una amplia gama de aplicaciones industriales. A medida que el trabajo de investigación y desarrollo continúa, el futuro de Rollos de CT en la fabricación de laminados es brillante y se espera que aporte mayor eficiencia, ahorro de costes y calidad de producto a la industria manufacturera.